|

Smart Washer to Predict & Prevent Bolt Failures

SCT's “Smart Washer” is an end-to-end remote monitoring solution for predicting and preventing bolt failures. This technology will reduce bolt failures, minimize operating cost, downtime, and allow better performance in maintenance activities. The "Smart Washer" features the newest technology in clamp force sensing technology that is 30% thinner, which allows lower cost and low power consumption than existing load monitoring technologies as in strain gauge load cells. This solution is integrated onto an ultra-low power wireless platform. This solution reduces bolt failures, prevents accidents, reduces cost and downtime related to maintenance activities. |

|

Remote Monitoring of Bolt Preload

The smart washer is part of an IoT network, whereby data is wirelessly transmitted to cloud servers for storing and analysis. The cloud-based platform has dashboard tools that allow remote access to all preloaded bolt data in real time, 24 x 7, all 365 days of the year. The tools provided on the cloud platform allows infrastructure supervisors to remotely recognize in real time any fastener that has become loose, which puts an end to frequent visits for manual on-site inspection. |

|

Full Compliance at Installation

The Smart Washer displays clamp force data to the staff involve during the installation which enables them to tighten fasteners to the specified clamp force according to the manufacturer’s standard. A immense improvement to the traditional less accurate method of using torque. The Smart Washer features on-board LED indicators which illuminate red, amber or green for simple identification of bolt clamp force. The data can also be sent over a local wireless network to a handheld tablet, enabling electronic audit trials to be generated. |

|

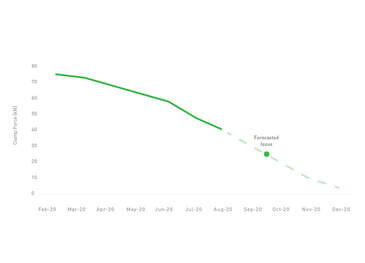

Bolt Failure Prediction

The real-time and historic data store on the cloud allow specialized algorithms to forecast bolt preload over time (90 days). This provides key supervisors and managers with sufficient time to forecast upcoming issues so a preventive maintenance can be planned several weeks in advance. This advance predicting and prevention feature for bolt failure, allows your critical assets to continue operating reliably and safely. |

|

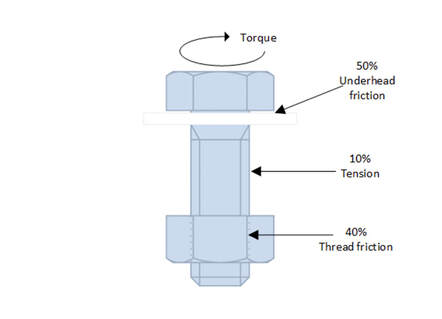

Torque readings are not reliable

The Smart Washer measures clamp force which is the real measure of fastener integrity. Torque is related to the twisting force applied to the bolt head or the nut. Torque is an unreliable measure of bolt tension due to there are many factors that can affect the torque equation because of the coefficient of friction, such as surface texture, rust, oil, thread condition and type of material. Real life operational situations have demonstrated that we can see errors of up to 70% when using torque-based installation procedures. Incorrectly tightened fasteners notably reduced their operational life. SCT’s Smart Washer clamp force sensing technology, provides accurate clamp force measurements. |

|

Any Bolt, application and Industry

Smart Washer technology is available for standard bolt sizes from M10 to M45. Versions of this device have also been created to meet the requirements of a specific application, industry or customer. Modifications range from alternative wireless technologies to incorporating the technology into existing asset components. The technology has been designed using a modular architecture, so that modifications to meet user requirements can be made in a way that is very cost and time efficient. |

All Rights, trademarks, product names, logos, brand referred to in this product are the property of © Smart Component Technologies Ltd.