|

SWIX to Predict & Prevent Railway Switch Failures

SWIX is a solution for end-to-end remote status monitoring that allows prediction and prevention of switch failure. The solution utilizes nodes of sensors located at critical areas of a switch to intelligently supervise the health condition of the switch and the substructure when rolling stock passes the location. The data is sent and stored to a remote cloud service where it is analyzed and can be viewed by the corresponding infrastructure maintenance managers. This technological platform allows the staff responsible of the infrastructure to predict and prevent failures. It will also reduce costs in preventative maintenance and reduce losses of railway network downtime. |

|

Remote Switch Supervision

The cloud service dashboard allows real time remote access to your network assets health, every day all year long. Area managers can use the route section view to see an overview of the health status of their corresponding assets. This allows them to quickly find any imminent issues on their assets, allowing for prioritization of maintenance activities. |

|

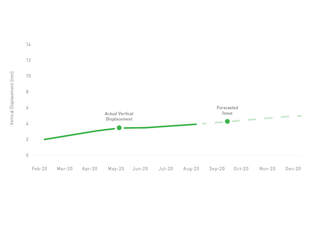

Failure Prediction and Prevention The solution utilizes collected data stored in the cloud servers to analyze historic and real-time asset health information which allows to predict the track quality over the next 60 days period of time. Infrastructure Managers will have sufficient warning of any impending matters that enables preventative maintenance personnel to plan several weeks in advance. |

|

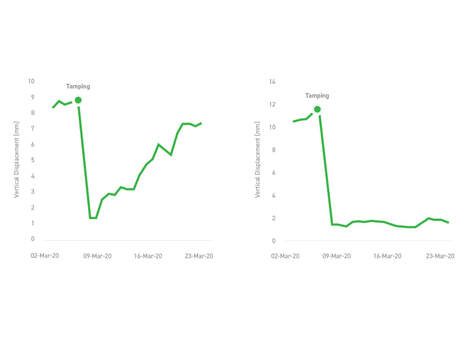

Tamping Optimization The processes of tamping and ballast renewals are very disruptive and expensive activities (up to £5M/km). Using the device (SWIX) historic, real-time and predictive monitoring capabilities, infrastructure managers can identify the optimal time to perform the tamping process. As an additional benefit, post tamping, the SWIX platform allows to view the new data to validate the successful tamping operation. |

|

Vertical displacement and Voiding

The vertical displacement of the track is formed of two parts; the void which is the air gap between the sleeper and the ballast, as well as the displacement of the ballast substructure due to its stiffness. Assessment of the two sources which make up the vertical displacement is necessary to identify the correct intervention. SWIX is the only solution that provides a quantified analysis of the displacement due to voiding and ballast substructure stiffness. Fast and Easy Installation

Maintenance operations times are short and working on track involves a lot of health & safety risks. The SWIX solution has specifically been developed to minimize time spent on site. The typical installation time is 10 minutes per S&C. For concrete bearers and sleepers, SWIX features a proprietary adhesive mounting solution which does not require drilling so does not weaken the bearer or sleepers in critical areas. An alternative mounting arrangement is available for timber sleepers and bearers. Where to monitor? Although S&Cs (switch and crossings) can be over 300 feet long, 90% of failures occur at the crossing nose and the toe of the switch. Therefore, the recommended installation is two SWIX sensors (one at the toe and another at the crossing nose). With these two devices installed, the infrastructure supervision staff can monitor the most critical and troublesome components of the S&Cs. The SWIX sensors can also be fitted at transition zones or on plain line. |

|

All Rights, trademarks, product names, logos, brand referred to in this product are the property of © Smart Component Technologies Ltd.